Security Lighting Considerations Guide

GCPSG-004 (2020)

Prepared By:

Royal Canadian Mounted Police

Lead Security Agency for Physical Security

Departmental Security Branch

NHQ 73 Leikin Drive Ottawa Ontario, K1A 0R2

Publication Issued: 2020-12-02

Updated: 2021-06-03

Table of contents

- Foreword

- Effective date

- Record of amendments

- Introduction

- Contact information

- Glossary

- Acronyms

- Security lighting overview

- Luminaire technology summary

- Luminaire deployment guidelines

- Security system integration

- Limitations

- Promulgation

Foreword

The Security Lighting Considerations Guide is an UNCLASSIFIED publication, issued under the authority of the Royal Canadian Mounted Police Lead Security Agency for Physical Security (RCMP LSA).

This is a Government of Canada publication to serve as a guide for the design of security lighting for departments, agencies and employees of the Government of Canada.

Suggestions for amendments and other information can be sent to the RCMP Lead Security Agency RCMP.LSA-GRC.POSM@rcmp-grc.gc.ca.

Effective date

The effective date of the Security Lighting Considerations Guide is 2020-12-02.

Record of amendments

| Amendment No. | Date | Entered by | Summary of Amendment |

|---|---|---|---|

| 1 | 2021-06-03 | S. Nattress | Addition of Alt Text for publishing in HTML and addition of SA&A Caveat. |

Introduction

The RCMP, as the Lead Security Agency (LSA) for physical security for the Government of Canada (GC) is responsible for providing advice and guidance on all matters relating to physical security. This includes the guidelines for exterior security lighting at GC buildings and campuses. The RCMP – in coordination with the GC security community – has developed and issued this guide.

Purpose

The purpose of this guide is to provide GC security practitioners with information on the appropriate selection and procurement of security lighting as part of physical security. This guide can be used as an addendum for the procurement of exterior security lighting. It is strongly encouraged that a qualified lighting designer is engaged as a part of any new or replacement lighting projects. Qualifications may include professional certifications, college diplomas, or manufacturer specific certifications.

This guide should be used during the full Facility Security Assessment and Authorization (FSA&A) process as well as other times when lighting is to be addressed such as:

- Input to the Threat and Risk Assessment (TRA);

- Input to the design of the exterior security lighting component for a new or upgrade/replacement construction project;

- Guidelines for project design reviews;

- Criteria for lighting acceptance testing and commissioning; and

- Assessment of existing exterior security lighting whether part of a regular security review or as a result of changes in the TRA for a site.

Applicability

This guide is for use by all GC security practitioners and contractors who design or procure exterior security lighting equipment for their department or agency, as well as security or lighting professionals when reviewing existing exterior security lighting.

It should be recognized there may be unique enhanced security situations that are outside the technical scope of this guide however, this guide will be updated regularly to capture new, or update existing information.

Information technology considerations

With the constantly evolving threat landscape, and the convergence of physical and information technology (IT) security, the requirement to assess the risk of any application and/or software connected to a network to operate and support equipment in Government of Canada controlled buildings is critical. Some examples of these control systems could be for items such as, but not limited to, security lighting, perimeter gates, doors, HVAC etc.

Before implementing any applications and/or software that will control and/or automate certain building functions, your departmental security requires the completion of a Security Assessment and Authorization (SA&A). This will ensure that the integrity and availability of the components the applications and/or software controls are maintained and that any risks highlighted will be mitigated. Starting the SA&A process early is highly recommended to ensure project delivery schedules are not affected. For more information on the SA&A process, please consult your departmental Security.

Contact information

For more information, please contact:

Royal Canadian Mounted Police

Lead Security Agency for Physical Security

73 Leikin Drive, Mailstop #165

Ottawa, ON

K1A 0R2

Email: RCMP.LSA-GRC.POSM@rcmp-grc.gc.ca.

Glossary

- Correlated Color Temperature

This is the temperature in degrees Kelvin of the Planckian radiator whose perceived color most closely resembles that of a given stimulus at the same brightness and under specified viewing conditions. The perceived colors go from yellow at the cool end to blue at the hot end. The colors range is often referred to as “warm” (yellow) to “cool” (blue) – reversed from the radiation temperature.

- Color Rendering Index

CRI is a mathematically calculated value based on the spectral power distribution (SPD) of the measured light source against a reference illuminant.

- Illuminance

The total luminous flux incident on a surface.

- Lumens

SI unit of luminous flux equal to one candela/steradian

- Luminaire

A complete electrical lighting unit including electrical parts and wiring.

- Lux

SI unit equal to one lumen/m2

- Facility Security Assessment and Authorization

The process of reviewing and validating the facility security components at each stage of a project.

- Uniformity Ratio

The ratio of the minimum lux reading over the average of all lux readings. A measure of the uniformity of illumination.

- Uninterruptible Power Supply

An electrical apparatus that provides emergency power to a load when the primary power source fails. They may use batteries or a flywheel as the emergency power source.

Acronyms

- AHJ

- Authority Having Jurisdiction

- CCT

- Correlated Color Temperature

- CCVE

- Closed Circuit Video Equipment

- CIE

- Commission internationale de l'éclairage (International Commission on Illumination)

- CPTED

- Crime Prevention Through Environmental Design

- CRI

- Color Rending Index

- FSA&A

- Facility Security Assessment and Authorization

- GC

- Government of Canada

- IR

- Infrared

- LED

- Light Emitting Diode

- LSA

- Lead Security Agency

- PoE

- Power over Ethernet

- SI

- Système international (d'unités) – (International System of Units)

- TRA

- Threat and Risk Assessment

- UPS

- Uninterruptible Power Supply

Security lighting overview

Physical security of GC buildings and campuses is a prime concern for the safety of the public, staff, and visitors. Exterior security lighting is a fundamental component of balanced physical security, which should be derived from a current TRA for each location based on both historical and anticipated threats.

Lighting, although a passive security element, is required for visual detection, assessment, and response to threats by guard forces and; monitoring, assessment, and recording by most closed circuit video equipment (CCVE). The following are the objectives of security lighting:

- Deters crime against individuals or assets by increasing the likelihood of observation;

- Provides clear visibility to an area to easily see anyone moving in or around it;

- Eliminates potential hiding places, especially near pedestrian walkways;

- Permits facial identification and body language interpretation at a distance to allow a response; and

- Supports the function of other physical security control measures such as CCVE, CPTED.

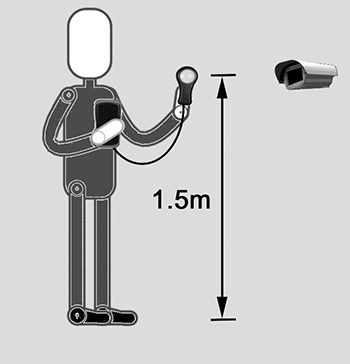

Current CCVE can capture excellent color images at light levels below those needed for viewing by people. Therefore, light levels that are acceptable for people are generally sufficient for today’s security cameras. The difference is that light levels for security purposes are not measured at ground level looking up, but are measured at head height, nominally 1.5m above the ground, facing towards the camera and/or observers. Measurement details will be covered in section 7 Luminaire Deployment Guidelines.

Crime Prevention Through Environmental Design (CPTED)

Lighting is a key part of CPTED (pronounced sep-ted) directly supporting several of its goals. The objective of CPTED is to enforce the fundamental of “form follows function” to positively influence behavior and activities while discouraging undesirable ones. CPTED has a collection of situational crime prevention entries; goals to be met during the designation, definition, and security design of the environment using CPTED principles. CPTED does not specify light levels but identifies lighting functions. The four CPTED principles and lighting goals are:

- Natural Surveillance – In order to see and equally important, be seen, sufficient light must be available. This applies to both people and CCVE systems;

- Natural Access Control – Lighting functions as a method to identify perimeters as well as accenting entrances, paths, and parking lots. Enhanced lighting at and near access points aids in the identification of visitors and in determining their purpose;

- Territorial Reinforcement – Lighting indicates the perimeter of a site by providing natural surveillance. It also combines with a fence to reinforce the boundary; and

- Maintenance – Lighting requires cleaning to maintain output levels and maintenance or repair in the event of failures or vandalism. Regular maintenance and rapid repairs indicate caring ownership by the people operating at the site.

LEED certification

Although not a security consideration, consulting a LEED designer may help reduce costs while increasing the efficiency of a security lighting design.

LEED certification of buildings is an indication of the energy efficiency and environmental footprint for upgraded and new commercial construction. It is based on points for various energy efficient and environmentally positive choices. These include points for meeting or exceeding the power density used for external lighting based on the exterior area zone designation. This is achieved with more efficient lighting sources and/or reduced operating time/light levels. Points are awarded for reducing light pollution. Light pollution is the light that is released to the sky (above the horizon) without having reflected off another surface (building, ground, etc). This is achieved with better control of light spread. Consult a LEED certified designer for current criteria.

Luminaire technology summary

Environment and Climate Change Canada (ECCC), as part of the GC national strategy, has as their number one goal to “Prohibit the manufacture and import of the most common types of lamps containing mercury. The first choice for future applications is LED due to higher efficiency, lower lifecycle costs, lower environmental impact, and beam control. LED luminaires are available for all uses, including infrared illumination. The below chart details lighting types and associated statistics, all other light sources are historical only, useful for understanding the difference between existing installed infrastructure and new light sources.

| Attribute | Color Rending Index (CRI) | Correlated Color Temperature (CCT) | Efficiency (Lumens/Watt) | Strike Time (min.) | Restrike Time (min.) | Spill Light/Beam Control | Operational Life (1000 Hours) | Outdoor Temperatures (See notes) | Dimmable Range (%) | Impact Resistance | Capital Cost | Lifecycle Cost | Environmental Impact (See notes) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Target | 80+ | 2500-6000K | 80+ | 0 | 0 | Good | 50+ | All | 10-100 | High | Low | Low | None |

| Light Emitting Diode (LED) | 65-95 | 2700-8000K | 80+ | 0 | 0 | V.Good | 50-100 | 2) | 0-100 | High | High | Low | 6) |

| Linear Fluorescent | 70-90 | 2700-8000K | 65-104 | 0 | 0 | Poor | 60 | 1) | 1-100 | V. low | Low | Med. | 4) |

| Compact Fluorescent | 82-92 | 2700-6500K | 46-87 | 0 | 0 | Fair | 15-Jun | 1) | 1-100 | Low | Low | Med. | 4) |

| Induction Fluorescent | 80 | 2700-6500K | 70-90 | 0 | 0 | Poor | 50-100 | 1) | 1-100 | V. low | Med. | Med. | 4), 7) |

| Incandescent Tungsten | 97-100 | 2500-2800K | <20 | 0 | 0 | Good | 0.75-5 | All | 0-100 | Low | Low | High | 3) |

| Quartz Halogen | 98-100 | 2650-3150K | <22 | 0 | 0 | Good | 6 | All | 0-100 | Low | Low | High | 3) |

| Metal Halide (Quartz/Ceramic) | 62-95 | 2800-4500K | 64-120 | <10 | <10 | Good | 20-30 | All | 50-100 | Med. | Med. | Med. | 3) |

| High Pressure Sodium | 22-30 | 1900- 2100K | 70-140 | <5 | <5 | Good | 40 | All | 50-100 | Med. | Med. | Med. | 3) |

| Mercury Vapor | 15-50 | 3200-6800K | 40-60 | <10 | <10 | Fair | 24 | All | 10-100 | Med. | Med. | Med. | 3) |

| Low Pressure Sodium | -44 | 1700K | 180 | <10 | <10 | Poor | 14-18 | All | N.A. | Med. | Med. | Low | 3) |

Outdoor Temperature Notes:

1) Output reduction/color shift in cold temperatures

2) Shortened life operating at high temperature (night-times are cooler)

Environmental Impact Notes:

3) Inefficient – banned as of 2014

4) Mercury hazard

5) High mercury and other heavy metals hazard

6) Manufacturing air, water, and ground pollution

7) May cause RF interference

Notes on attributes

- Color Rending Index (CRI)

CRI is used to rate how well a lamp will allow correct identification of colors by a viewer. There are no CRI meters, it is a rating provided by the manufacturer.

- Correlated Color Temperature (CCT)

CCT is measured in degrees Kelvin and rates the source on a scale from a candle (1500K) at the bottom to a blue north sky (8500K) at the top. The light source is described on a range from warm to cool.

- Efficiency (Lumens/Watt)

Efficiency relates directly to the cost of electricity as well as the size and cost of any auxiliary power sources. This includes generators and Uninterruptable Power Supply (UPS). This is part one of lifecycle costs.

- Strike Time (min.)

Strike time is the time to start from cold. This is only important if the lamp is going to be started with no warning – starting delays at night-fall can be adjusted for in the control system.

- Restrike Time (min.)

Restrike time is the time to restart after a power interruption. This is important where illumination must be maintained.

- Spill Light/Beam Control

Beam control manages backlight, up-light, and glare from the lamp. Most lamps control the beam with reflectors and the larger the light source (e.g. linear fluorescents), the lower the control. LED lamps have many LEDs in a single luminaire. Each LED can have its own lens and can be aimed to provide more uniform coverage resulting in lower overall lumens required.

- Operational Life (1000 Hours)

Operational life determines the frequency of replacement of either the bulb or the whole luminaire and contributes to the lifecycle cost. Ten years on night-time operation is considered to be 43,000 hours. Most luminaires allow the lamps to be replaced, however most LED luminaires must be completely replaced as the lamp is not removable. The operational life of a lamp is usually defined as the point when the light output reaches 70% of the starting value.

- Outdoor Temperatures

Canada, while mostly cooler than other countries, sees temperatures in the range of -40°C to 40°C. Any exterior luminaire must operate through that range. Nighttime use will typically see the cooler end of that range. Wind chill is not a factor for inanimate objects.

- Dimmable Range (%)

Dimming is only important should the site decide to use variable illumination.

- Impact Resistance

Impact resistance is important for the survival of the lamp when vandalized. Portions of the luminaire such as polycarbonate covers will increase the resistance. Solid state LED lamps are inherently more resistant to shock and vibration.

- Capital Cost

Capital cost is the initial acquisition and installation cost of the luminaire. This is the second part of lifecycle costs.

- Lifecycle Cost

The lifecycle cost is the averaged cost per time of the luminaire, installation, maintenance, repair, and energy costs. LEDs are a semi-conductor technology and are still seeing significant capital cost reductions with manufacturing improvements and competition. The actual payoff period for LEDs is constantly improving with many industry white papers suggesting 2-3 years.

- Environmental Impact

Environmental impact includes the lifetime manufacturing and disposal challenges of the luminaire and the lamps consumed.

LED light systems

With LED sources, a designer or engineer can determine the useful life of the system, calculated using the manufacturer’s Lumen Depreciation data (L70 for 70% of initial lumen output is a common data point). Security Practitioners should be aware that when designing the lighting system, it should identify the minimum length of time (number of years) that the system is required to deliver the specified light level, taking into account the appropriate light loss factors including lumen depreciation data”.

Other lamp technologies

There are new mercury free technologies being developed that may soon be a choice. These are field-induced polymer electroluminescent technology and electron stimulated luminescence. More work need to be done in this area to improve cost, efficiency, and operational life. This technology is currently “area lamps” so focusing and aiming will be a challenge. Xenon arc lamps are an existing technology, but they are primarily used for projectors and spotlights as opposed to area illumination.

Luminaire selection criteria

Given LED is the current preferred technology, here are some parameters to consider when selecting an LED luminaire. The starting attributes can be taken from Table1:

Illumination Technology Attributes targets:

- CRI of 80+;

- CCT between 2500K and 6000K;

- Lumen efficiency of 80+ lumens per watt; and

- Minimum warranty of 50,000 hours based on 70% of the original output lumens (due to the power law, the effective range will be ~84% of the original range). Warranties beyond 100,000 hours are not reasonable with the current technology.

The annual average for dark hours is assumed to be 4300 hours.

Specific criteria that will be required for all installations include:

- UL/CSA certification;

- Ambient temperature for the site as this impacts luminaire lifetime;

- Luminaire operating voltage – in cooperation with electrical planning; and

- Maintenance access – does access to the luminaire require a boom truck, can the mast be lowered; is a ladder enough? This can be offset with the access frequency and available equipment. (i.e. we have a boom truck and a power washer).

Additional criteria for selecting LED luminaires will rely upon the specific use case which is usually be determined by a qualified lighting designer. These will include:

- Rated luminous flux for the total light output;

- Beam uniformity, sometimes called hot-spot reduction; and

- Beam width, measured at 50% and 25% of the peak power to determine useful width.

Optional criteria to be considered for luminaire selection include:

- Power level control for flexibility of deployment;

- Power over Ethernet (PoE) when using Ethernet switches to provide power; and

- Internet connectivity as an alternate control method.

Note 1: Any network connected lighting control system must be protected against unauthorized access. The best method is a dedicated, air-gapped control network that is isolated to the building or site.

Note 2: LED luminaire lifetimes are linked to high temperatures in the actual LEDs. Designs with better thermal management that keep the LEDs cooler will last longer. Current estimates have approximately half of LED luminaire failures happening in the power supply circuitry.

Video image flicker

Many arc-based luminaires have flicker as the arc forms and collapses with each half cycle of the power source. This results in 120 flashes per second (in North America). Use of these lights to illuminate areas viewed with security cameras can result in visible pulsing of the image. This is because the frame rate of the camera is not synchronized to the frequency of the mains power. These two frequencies can drift in and out of sync resulting in gathering the image with more or fewer flashes of light per frame. The hotter and higher power arcs have less total flicker as they have thermal and sometimes phosphor lag effects that maintain some light output during the current reversal. Several lighting technologies including LEDs have avoided this problem by using high frequency ballasts/power supplies that boost the switching frequency into the tens of kilohertz or higher.

Infrared illumination

Infrared (IR) illumination (also called active IR) is an option likely to be used only in special cases where visible lights are not acceptable such as covert operations. IR lights can be easily detected by most cameras, including cell phones, and night vision goggles. IR is mostly invisible to the unaided eye, but may appear to be dim red if the luminaire is observed directly. IR illumination has greater range when compared to visible lighting however it carries no color information and the cameras generate a black and white image.

IR illumination is integrated into many security cameras; however, these lights often attract spiders who weave webs over the lens and should be avoided for outdoor use. Separate IR illumination has a much longer illumination range and can provide more uniform illumination levels. Typical integrated camera IR have a range of only 50m while separate illuminators can easily reach 500m.

IR Illuminators generating 850nm light should be used. The 850nm light is also closer to the visible spectrum and causes less focus shift between daylight and night operation. Security cameras are much less sensitive to the alternative 950nm IR and some security cameras in night mode will filter frequencies outside of 800-900nm band.

Should complete invisibility be required, 950nm illuminators can be used, but selection of compatible cameras is required. 950nm luminaires will require approximately twice the power of 850nm luminaires to achieve the same illumination levels for the cameras.

Recommended IR power levels at the maximum range should be between 0.3 and 0.35 μW/cm2. This can be determined with an appropriate IR meter.

Note 1: IR light does not cause a pupillary reaction in the eye so high-power emissions can be dangerous. IEC-62471: Photobiological Safety of Lamps and Lamp Systems safety limits for continuous exposure has a limit of 10,000 μW/cm2. Measurement or calculation of the output will indicate the closest approach while operating. This distance is usually less than 3m and often achieved by positioning the illuminator on a mast.

Note 2: Materials often have significantly different reflectance values under infrared illumination. Objects, both natural and man-made, that appear to have a similar color under visible light may be significantly different under IR. There is no intuitive map from visible colors to IR reflectivity.

Note 3: Active IR must not be confused with passive IR. Passive IR is a heat emitted or reflected from an object in the range of 8,000nm to 14,000nm. The imager converts the heat into a grey scale or false-color image that is independent of any visible illumination and works the same in both daylight and total darkness.

Luminaire deployment guidelines

Light measurement

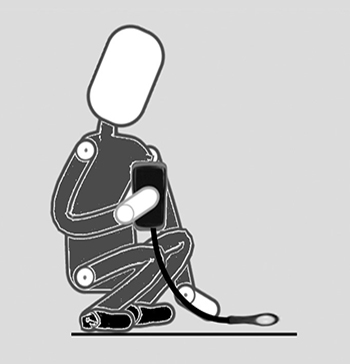

Security lighting has a different purpose than regular lighting. The purpose is to increase the ability to observe faces and body language. As such, it is measured differently than regular lighting. Regular lighting is measured at ground level with the meter facing up. For security lighting, the meter is held at head height (nominally 1.5m above ground) and pointed towards the camera or observers. If the threat includes people crawling, then additional measurements should be taken at 0.4m above ground in the same orientation. Given the low-light sensitivity of current security cameras, if the illumination levels are sufficient for an individual to identify another individual, they are sufficient for a security camera to operate effectively in color mode. Spill light from adjacent properties can be considered in the illumination measurements except for enhanced security situations where full control of the lighting must be maintained.

Light measurements are performed over a grid of points in the target area. The grid size depends on the target area size but it usually measured in whole meters for each square. This collection of measurements is used to determine uniformity which is the ratio of the minimum level divided by the average of all levels giving a value between 0 and 1. This is particularly important as it will indicate if there is glare or dark areas and higher uniformity will make it easier for both individuals and security cameras to see a quality image. Contracts may include light measurements as a deliverable or be taken with a calibrated cosine-corrected light meter by lighting or security specialists using a recorded, repeatable grid as part of acceptance tests.

A person standing vertically taking a luminescent measurement with a light meter at a height of 1.5m

A person kneeling down taking a luminescent measurement with a light meter at ground level

Caveat 1: When performing any security lighting luminance measurement, be wary of seasonal, sky, and weather conditions, and even light clothing on the tester that can significantly change the reflected and diffused light levels. This particularly applies to snow cover, full/no moon, and wet conditions.

Caveat 2: When performing regular lighting measurements from ground level, it may be appropriate to measure a short distance, such as 0.1m above ground to avoid any local clutter, flora, or surface undulations.

Caveat 3: If there are bright areas behind security measurement locations, additional security lighting measurements may need to be taken facing away from the camera or observers. The purpose it to verify that any backlighting is less than four times the measured front light. High backlight values will put the target into silhouette or be a glare source to the observer. This can be offset by shielding or redirecting the glare source or increasing the front illumination levels

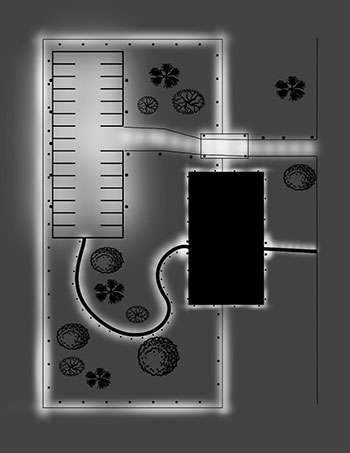

A facility with lighting illuminating the perimeter fencing, gated vehicle entry, pedestrian walkway, parking area and the building

Maintenance

Luminaire maintenance falls into three categories, preventative, corrective, and life-cycle. Preventative maintenance is planned and includes activities such as cleaning and inspecting the luminaire, verifying the luminaires are aimed as expected, and life-cycling lamps that are near end-of-life. Corrective maintenance is unplanned and includes replacing lamps that have burned out, ballasts that have failed, and fixing electrical connections that may be damaged or corroded. Life-cycle replacement is planned and may include the consumable material (bulbs, ballasts, etc.) or replacement of the entire lighting system. This needs to be considered when designing and selecting the exterior lighting system. Regular inspection assures that the lights are operating. Cleaning assures that the lights are emitting all the generated light to achieve the expected light levels. The frequency of cleaning and inspections will vary based on the location and the quantity of dust, fauna, and weather. There is no specific standard for this, and should be based upon specific requirement. Quarterly may be a good starting point and can be adjusted based on the conditions found during each preventative maintenance cycle. Maintenance may be done by the security practitioner or may require a lighting professional, depending on the application.

Proper maintenance of an LED system requires measurement and recording of conditions to determine when the system is no longer producing the required output, allowing for a planned replacement schedule. Many LED installations have light sources that are not field replaceable, and require the complete fixture to be renewed at the end of life. This is a capital cost and not a typical annual operations expense. Even those fixtures with replaceable LED boards use proprietary components that must be sourced from manufacturers, a situation with extended lead times and that may not be easily procured at international (diplomatic) properties.

| Location | Security consideration |

|---|---|

| Pedestrian areas and paths. | Luminaires should be vandal resistant and mounted 2.4-4m above ground to make vandalism more difficult. Average light level should be at least 20 lux on the path and at least 5 lux at 5m perpendicular to the path. Minimum 0.33 uniformity ratio. All measured horizontally from 1.5m off the ground towards the camera or observers. If not an observed path, measure the perpendicular levels towards the path. Luminaires mounted below head level, such as in bollards, may not illuminate faces sufficiently. Luminaires mounted higher than 4m will reduce the horizontal lux measurements, put faces into shadow, and may be partially blocked with by trees. Typical mast spacing is four times the mast height. |

| Open staff/public parking lots | Average light level should be at least 25 lux. Minimum 0.25 uniformity ratio. Measured horizontally from ground level. Locate luminaires high enough and close enough to illuminate car door handles between parked vehicles by spacing masts at four times the mast height with the first/last mast being two times the mast height from the end of the lot. |

| Enclosed parking lots | Average light level should be at least 65 lux. Minimum 0.25 uniformity ratio. Measured horizontally from ground level. Average light level should be at least 50 lux. Minimum 0.25 uniformity ratio. Measured vertically from 1.5 m off the ground towards the observing individual or device. Light color paint will help light diffusion to increase uniformity. |

| Stairwells and elevator lobbies | Average light level should be at least 100 lux. Minimum 0.25 uniformity ratio. Measured horizontally from ground level. Light color paint on walls and ceilings will help light diffusion. |

| Staff entrances and exits – exterior lighting | 50-200 lux using wall mounted luminaires 3-4m above ground level. These will cast long shadows for any movement nearby. Light color or glass wall finishes will help light diffusion. |

| Emergency vehicle parking lots (e.g. patrol vehicles, police vehicles, ambulance, etc.) | Average light level should be at least 80 lux. Minimum 0.33 uniformity ratio. Measured horizontally from ground level. This is significantly higher than open staff/public parking lots. It enables fast, safe actions by the vehicle drivers and passengers. |

| Vehicle inspection areas (e.g. sally ports) | Average light level should be at least 100 lux. Minimum 0.33 uniformity ratio. Measured horizontally from ground level. Low-level side lights, in-ground lights, or an undercar camera system will aid any under-vehicle inspection however winter weather considerations may impact the choice(s). Extra system specific lighting may be added for license plate cameras – often IR illuminators. |

| CCVE surveillance zones | Average light level should be at least 20 lux. Minimum 0.33 uniformity ratio. Measured vertically from 1.5m off the ground towards the camera or observers. Mount luminaires above and behind security cameras to prevent light flare in the image. If the luminaire must go below the camera, position it at least 1m below and behind. Although many security cameras can generate color images at lower illumination levels, this level is chosen to maintain frame rates and shorten shutter times to reduce the amount of blur from fast movement in the field of view. |

| Storage yards and terminals | Average light level at least 10 lux. Minimum 0.16 uniformity ratio is required. At 80 lux. Minimum 0.33 uniformity ratio is required. Measured horizontally from ground level. Luminaires should be deployed on high masts of 9m or more. Guidance for vehicle parking areas within the yard/terminal are the same as Staff/public parking lots. The yard/terminal may become a CCVE surveillance zone if there are enhanced security needs. |

| Patrolled/Sensored secure perimeters | Lighting on perimeters should be installed on the secure side of the perimeter and aimed towards the observed side of the perimeter leaving the patrol side relatively darker. There should be a band of light with an average light level of 20 lux from 3m on the patrol side to 9m on the approach side. This illuminates individuals approaching the patrolled perimeter while glare can conceal the security response. Well aimed luminaires can control light spread beyond the perimeter. Open fabric perimeter fences should have a low reflectance finish to allow better viewing through the fabric. Tight beam control should be used to limit light spill onto neighboring properties and roads – this assumes any perimeter fence or barrier is set back from the property boundary. |

| Uncontrolled perimeters | Lighting on uncontrolled perimeters should be configured as a human surveillance CCVE surveillance zone to encourage natural surveillance from both within and outside the site. Tight beam control should be used to limit light spill onto neighboring properties and roads. |

| Power Distribution | Exterior security lighting should have power supply redundancy. The groups of luminaires should be powered from separate phases and circuits on the site. Ideally, the power supply to an area should be interleaved between luminaires such that loss of a single phase will not leave a large area in darkness, but will only reduce the overall light levels and uniformity. |

| Lamp life | The industry standard for the lifetime of a lamp is the point at which the output has decreased to 70% of the original value. This decrease is included in the guideline light levels. 70% of light output stills means 84% of the original distance lit. |

| Plants and trees | Foliage should be considered for both seasonal variations and annual growth. Deciduous trees will lose their leaves every winter and all trees and plantings will continue to grow necessitating regular pruning to maintain sight lines. Untended areas can have significant weed growth in less than a month. |

Note: The above values are minimum lighting guidelines. Exceeding these guidelines by large margins is not necessarily an improvement. The higher light levels can attract unwanted interest, increase light pollution, possibly spill excessive light beyond the site boundaries, and cost more to operate while providing no improvement in security or effectiveness for any response.

Levels and details are adapted and merged from several sources including:

- IESNA Guide for Security Lighting for People, Property, and Critical Infrastructure IES G-1-16;

- Centre for the Protection of National Infrastructure Security Lighting Guidance for Security Managers February 2015; and

- The Association of Chief Police Officers of England, Wales and Northern Ireland (ACPO) Lighting Against Crime – A Guide for Crime Reduction Professionals 2011. The ACPO was dissolved and replaced by the National Police Chiefs’ Council (NPCC) in 2015.

Security system integration

Lighting is part of physical security at any location. There are many things to consider when integrating security lights into an established physical security plan.

Given the constantly changing hours of daylight, lighting should be operated on a photo sensor to turn on when ambient light levels drop below 40 lux. The sensor(s) must be shielded from visibility from ground level to prevent an individual from disabling the lights by shining a light on the sensor. There are “seasonal timers” that can adjust on/off times over the year however storms, overcast conditions, and even eclipses justify the need for a photo sensor as well.

Security lighting may use multiple levels; this is the primary way to reduce energy requirements for lighting and can also improve LEED ratings. Full intensity lighting may be used during staff hours and may be dimmed or extinguished during quiet hours. This would be determined on a site-by-site basis considering the operational hours, threats, and the security level. Dimmed or extinguished lights should be integrated into the security system so that they may be returned to full intensity in response to a security system alarm, or as directed by security personnel. Random light operation is not recommended as it can annoy neighbors and has limited deterrent value.

Further integration of light level controls can be done with other types of sensors. These sensors can be used to change light levels in response to approaching vehicles or the presence of people. These could be capacitive sensors, thermal detectors, photo-electric sensors, video analytics, or other technologies. The use of these types of sensors could apply to security and safety situations on a site.

Additional special lighting such as spotlights may be added to the security lighting system as an additional measure to help identify persons detected further from the perimeter. The spotlight indicates they have been noticed and a response is to be expected. This would only be appropriate with an on-site security force.

Security measures that support other security measures (such as security lighting and CCVE) that may lose functionality during a power interruption should include an Uninterruptible Power Supply (UPS). The design duration of the UPS will allow for generator startup plus additional time to determine generator failure and implement emergency actions such as acquiring flashlights and securing entrances. The UPS capacity may be reduced if it is determined that supporting some subset of the exterior lighting is sufficient for the response to light loss. The required UPS time should then be doubled as the battery operating duration will reduce over the UPS’s battery life – typically 3-5 years before requiring battery replacement. It should be noted that a generator is the only long-term alternative power source as a UPS support is measured in minutes.

Note: Cameras may take several seconds to change to day mode when the lights come on full.

Limitations

Limitations in deployment of security lighting may come from building codes, local bylaws, environmental concerns (e.g. migratory birds, nocturnal animals), and waste management of expired luminaires. All of these should be addressed through the Authority Having Jurisdiction (AHJ).

As of December 31, 2014, Canada has banned the import and sale of general service lamps and modified spectrum incandescent lamps with special exceptions.

Further exterior lighting related discussions can be found by searching municipalities such as Mississauga and Calgary as well as private groups such as the Royal Astronomical Society of Canada. Every site will require local research through the AHJ.

The most common solutions are to reduce the light levels and control the backlight, up-light, and glare. LED luminaires are the best technology for achieving these goals.

This guideline may not be fully applicable outside Canada due to local regulations in other jurisdictions. Please contact the local AHJ in these cases.

Promulgation

Reviewed and recommended for approval

I have reviewed and hereby recommend GCPSG-004 (2020) Security Lighting Considerations Guide for approval.

Shawn Nattress,

Manager

RCMP Lead Security Agency

2020-12-02

Approved

I hereby approve GCPSG-004 (2020) Security Lighting Considerations Guide

André St-Pierre,

Director, Physical Security

RCMP

2020-12-02

- Date modified: