Blast Mitigation Considerations Guide

GCPSG-002 (2021)

Prepared by:

Royal Canadian Mounted Police

Lead Security Agency for Physical Security

Departmental Security Branch

NHQ 73 Leikin Drive Ottawa Ontario, K1A 0R2

Publication issued: March 4, 2020

Updated: June 30, 2021

Table of contents

- Foreword

- Effective date

- Record of amendments

- Introduction

- Contact information

- Definitions

- Blast

- Establishing blast requirements

- Mitigations - Setback (stand-off) distance

- Considerations

- Supporting content

- Promulgation

- Footnotes

Foreword

The Blast Mitigation Considerations guideline is an unclassified publication, issued under the authority of the Royal Canadian Mounted Police Lead Security Agency for Physical Security (RCMP LSA).

This is a Government of Canada publication to serve as a guideline on considerations specific to Blast Mitigation for departments, agencies and employees of the Government of Canada.

Suggestions for amendments are can be sent to the RCMP Lead Security Agency RCMP.LSA-GRC.POSM@rcmp-grc.gc.ca.

Effective date

The effective date of the Blast Mitigation Considerations Guide is March 4, 2020.

Record of amendments

| Amendment no. | Date | Entered by | Summary of amendment |

|---|---|---|---|

| 1 | June 30, 2021 | S. Nattress | Addition of Alt Text for publishing in HTML and addition of SA&A Caveat. |

| Note: Authority for modifications or variances is Royal Canadian Mounted Police Lead Security Agency for Physical Security (RCMP LSA). | |||

Introduction

The RCMP, as the Lead Security Agency (LSA) for physical security for the Government of Canada (GC) is responsible for providing advice and guidance on all matters relating to physical security. This includes what should be taken into consideration after it has been determined that specific blast mitigations measures are required for a specific location or application.

Purpose

The purpose of this manual is to provide GC employees with information on blast dynamics and the appropriate considerations to be taken into account when a decision has been made to implement blast mitigation measures. What to expect and who to consult with when developing an appropriate plan to add blast mitigation to a project, building or application.

Applicability

The considerations identified within this guideline are to be used in the planning, designing and implementation of blast mitigation used by Government of Canada (GC) Departments and Agencies.

The document is intended to be updated regularly to capture new guidance or update existing information as the program evolves.

Information technology considerations

With the constantly evolving threat landscape, and the convergence of physical and information technology (IT) security, the requirement to assess the risk of any application and/or software connected to a network to operate and support equipment in Government of Canada controlled buildings is critical. Some examples of these control systems could be for items such as, but not limited to, security lighting, perimeter gates, doors, HVAC etc.

Before implementing any applications and/or software that will control and/or automate certain building functions, your departmental security requires the completion of a Security Assessment and Authorization (SA&A). This will ensure that the integrity and availability of the components the applications and/or software controls are maintained and that any risks highlighted will be mitigated. Starting the SA&A process early is highly recommended to ensure project delivery schedules are not affected. For more information on the SA&A process, please consult your departmental Security.

Contact information

For more information, please contact:

Royal Canadian Mounted Police

Lead Security Agency for Physical Security

73 Leikin Drive, Mailstop #165

Ottawa, ON

K1A 0R2

Email: RCMP.LSA-GRC.POSM@rcmp-grc.gc.ca.

Definitions

List of abbreviations and acronyms

- AHJ

- Authority Having Jurisdiction

- DBT

- Design Basis Threat

- LOP

- Level of Protection

- TRA

- Threat and Risk Assessment

- VBIED

- Vehicle Borne Improvised Explosive Device

- PBIED

- Person Borne Improvised Explosive Device

- FRP

- Fiber-reinforced Polymers

- CFRP

- Carbon Fiber-reinforced Polymers

- ASF

- Anti-shatter Film

- SME

- Subject Matter Expert

Blast

Blast overview

The study of blast and blast effects on structures is extremely complex and the science is constantly evolving. Blast physics and the systems to analyze the propagation and interaction of blast waves with structures is especially complex when taking into consideration building shapes and cityscapes. Variabilities in the use of construction materials and methods presents a massive array of possible outcomes under differing blast conditions. Furthermore, the exact definition of where or when an attack is likely to occur, the style of weapon used, and the overall effectiveness of the weapon adds further complexity.

Setback is your savior when mitigating blast effects.

The overall result of this variability makes developing mitigation strategies that address blast threats in an absolute fashion unrealistic. The best method is developing a mitigation strategy that addresses all known threat scenarios while attempting to take into account unknown future conditions using the best intelligence available.

There is however one concept that all designers of blast mitigation agree: setback is your savior when mitigating blast effects. Any measures to improve setback (standoff distance between a potential threat and the asset) should be considered and implemented where possible.

Given the significant potential damage, impact and injury that even a modest blast event might generate, it is recommended that blast-mitigating systems be considered for the entrances, reception areas, freight areas, exterior walls, windows and roof of any facility that has been identified as having a likelihood of explosive attack based on a TRA. The safeguards recommended follow practices used by international and domestic agencies with similar threat profiles to GC departments and agencies. These safeguards are recommended in order to limit the effects of blast events.

Objective of every blast-mitigation or blast-retrofit design is to:

- Safeguard all building occupants

- Minimize property damage

- Assist with maintaining business continuity

Delivery methods

Explosive or bomb delivery methods typically used by attackers against buildings usually fall into one of two categories: person borne or vehicle borne.

- Person Borne Improvised Explosive Device (PBIED)

- is generally a homemade bomb constructed and deployed by a human in ways other than in conventional military action. These may include; suicide vests, pipe bombs, backpack/bag bombs etc.

- Vehicle Borne Improvised Explosive Device (VBIED)

- is an improvised explosive device placed inside vehicle and then detonated. It is commonly used as a weapon of assassination, terrorism, etc. to kill the occupants of a vehicle, people near the blast site, or to damage buildings or other property. Examples would include the 1996 Oklahoma City bombing and the 2007 VBIED devices found in Trafalgar Square in London, UK. +

Effects due to blast

The explosion of conventional (chemical) explosives involves a rapidly occurring chemical reaction. The explosion is referred to as a detonation or a deflagration depending on the speed at which the reaction occurs. Detonations and strong deflagrations result in explosion effects comprising mainly the air blast and the projection of fragments and debrisFootnote 1.

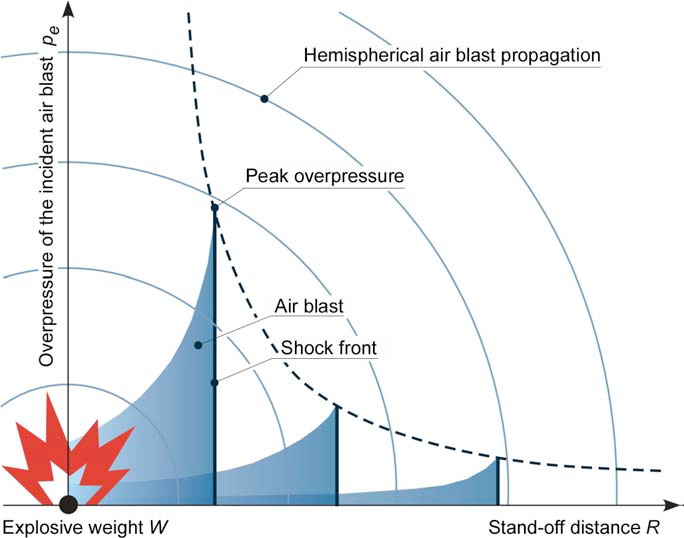

An explosion creates an air blast, which is propagated spherically from the center of the explosion. As the blast wave spreads, it does so in accordance with a characteristic pressure-time curve, whereby the peak overpressure diminishes as the distance from the center of the explosion (standoff distance) increases. See Fig. 4-1.

The following two references are presented to illustrate the destructive power of a relatively modest charge that could be transported easily by a person. Note that the data varies slightly given the scale and presentation of the graphs used as reference.

- A 22.5 kg (50 lb.) charge can cause [unmitigated] concrete columns to fail at a standoff of less than 4.5 m (15 ft.) and wall fragmentation occurs up to 20 m (65 ft.) standoffFootnote 2.

- A charge of 20 kg (44 lb.) results in destruction of most [unmitigated] buildings within a standoff of 8 m with damage to reinforced concrete structures to 22 m (72 ft.) and failure of masonry walls to 30 m (100 ft.)Footnote 3.

The forces exerted on structures from even a relatively small charge can be extreme. Modest blast pressures borne by a wall may result in the equivalent of many metric tons of force. Poorly designed mitigation may cause extensive wall, window or even structural failure resulting in serious injuries or fatalities.

Figure 4-1 - Text version

Figure 4-1 graph depicting Air Blast Propagation – The vertical axis of the line graph indicates the overpressure of the incident air blast. The horizontal line of the line graph illustrates the explosive weight and stand-off distance. The vertical line and the horizontal line of the graph intersect at the point of explosive weight. The power generated by the explosion creates sphere like waves including air blast, shock front, peak overpressure and hemispherical air blast propagation. These waves emanate outward from the point of explosion. The greater the distance (stand-off distance) from the blast source, peak overpressure diminishes.

Overpressure and impulse

Overpressure is a commonly understood blast parameter that is readily associated with building damage. Blast capacity is often described in terms of overpressure level without much attention paid to the duration of the blast load however, duration of the load is extremely important to damage produced by blast loads. Blast overpressure is conceptually easier to understand, as people are familiar with the physical meaning of pressure.

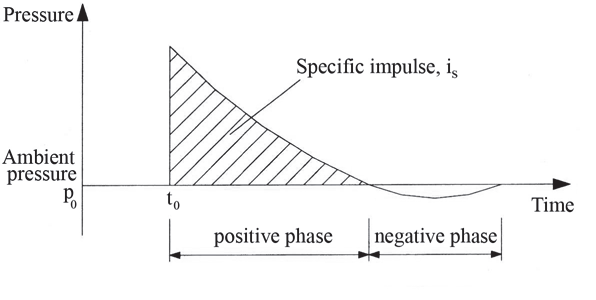

Figure 4-2 - Text version

The vertical line of the graph represents ambient pressure and pressure. The horizontal line of the graph depicts time in terms of the positive phase and negative phase. An increase or rise in ambient pressure creates overpressure along the vertical axis. A rapid decrease from ambient pressure to underpressure or negative pressure as depicted along the horizontal line of the graph, is often lower in amplitude but longer in duration during the positive phase. Specific impulse is the calculated by measuring the total applied load or blast. P0 is the pressure at detonation, t0 is the exact time the blast occurred and is depicts the load of the blast from detonation over time so essentially how the blast load reduces from detonation to dissipation).

Blast loads from high explosives: Detonations are typically characterized by an instantaneous rise in pressures above ambient pressure (overpressure) to a peak value followed by a rapid decay back to ambient followed by an underpressure (negative pressure). This underpressure is most often much lower in amplitude but longer in duration than the positive phase portion of the load. A typical blast load in the form of a pressure‐time history is shown in Figure 4-2. A blast load of this type is characterized by the peak pressure, load duration and impulse.

Impulse is a measure of the total applied load and is a key parameter when considering the response of structural and non‐structural components to blast loads. Blast practitioners should not refer only to blast overpressure, but include duration and impulse as part of a fulsome review of a blast scenario.

Explosive effect on buildings

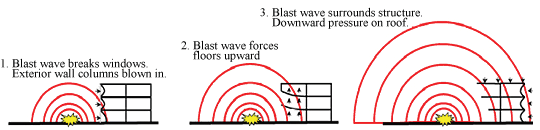

The "front" face (nearest the explosion) of a building experiences peak overpressures due to reflection of the external blast wave. Once the initial blast wave has passed the reflecting surface of the building, the overpressure on the face decays to zero. As the sides and the top faces of the building are exposed to overpressures (which have no reflections and are thus lower than the reflected overpressures on the front face), a relieving effect of blast overpressure is experienced on the front face called "negative pressure". The rear of the structure experiences no pressure until the blast wave has traveled the length of the structure and compression waves have started to "wrap around" the building. Therefore, the pressure build up is not instantaneous and there is a resulting time lag between the development of pressures and loads on the front and back faces. This time lag causes translational forces to act on the building in the direction of the blast wave.

Figure 4-3 - Text version

Figure 4-3 depicts how the blast wave forces affect a building. Phase 1 of the blast wave results in windows breaking and damage to the exterior wall columns that are blown in. Phase 2 of the blast wave forces the floor of the building or structure upward. Phase 3 of the blast wave surrounds the entire building by placing downward pressure on the roof of the structure).

Establishing blast requirements

When establishing blast requirements, you should conduct threat analysis/research to determine what explosive attacks are likely, precisely define the attacks in terms of delivery method, charge weight, and location (scenario), and determine what outcome is desired for each of the attack scenarios.

This section will cover variability in calculation and design approaches, the various standards, methods, models available, and the security design objectives, as well as how to define the detailed design basis threats, levels of protection, and how to engage an SME and conduct studies."

Design variability

Historically, establishing suitable blast mitigation strategies that address all stakeholder concerns has been extremely difficult and problematic. Threat definitions have often been based upon the background and experiences of those conducting the assessments, resulting in inconsistent recommendations or those that could not be widely interpreted and applied.

Unlike some international security partners, Canada does not have a long history of attackers using large amounts of explosives. The relatively small number of blast incidents in Canada has resulted in a range of divergence approaches and philosophies across government. Until recently, many stakeholders minimized or rejected blast threats while most security practitioners considered blast threats highly likely over the long term, which again has resulted in inconsistent mitigation approaches or those that could not be widely interpreted and applied. Moreover, it is extremely difficult to establish blast threats over the long term in the face of changing global dynamics.

Within the community of blast design experts, there exists variability in calculation and design approaches, and potential for error. Different blast practitioners prefer different calculation methods, which sometimes lead to discrepancies as blast load calculations are highly dependent on the blast practitioner analyst and the load determination models being used. Further, not all explosives act in the same way - some are less effective than others by charge weight therefore TNT equivalency is typically used to determine blast loading. TNT equivalency and conversion methods used to account for the different types of explosives adds further variability in the design calculations and therefore the recommended mitigations.

In order to decrease potential variability and improve consistency in blast mitigation across a range of projects, the GC department or agency's Physical Security Program should:

- apply consistency and rigor in the Threat and Risk Assessment (TRA) processes

- engage multiple stakeholders and experts during TRA processes

- reference previous TRA's to determine trends and commonalities

- fully review and justify any significant deviations from previous assessments

- TRA's should include blast threats matching the expected life of building

- blast analysis should be peer reviewed

- ensure blast analysis methods are consistent with, or equivalent to, national standards and previous efforts (where possible)

- apply consistent charge weight TNT equivalency methods/models

Design standards

There are commonly used international standards, e.g. UFC, DoS, and CPNI, however in Canada, CSA S850-12 Design and Assessment of Buildings Subjected to Blast Loads, should be used as the primary design reference for security practitioners and designers. This Standard applies a consistent approach to blast design with a view to removing as much variability as possible and should be referenced as the criteria for the analysis and design of new buildings, and the assessment of existing buildings to resist blast loading.

The standard CSA S850-12 requires that Design Basis Threats (DBT's) and Levels of Protection (LOP's) be established by the building owner (or AHJ) with enough detail to enable blast engineers and consultants to develop suitable and cost-effective blast mitigation systems.

Design objectives

The objective of designing against blast loading is to limit the extent and severity of blast damage in order to reduce human casualties, damage to assets, and allow the emergency evacuation of occupants of the building following a blast-loading eventFootnote 4.

Performance objectives should be defined for each structure, building or portion of building requiring protection from blast. The design team should be provided with objectives or design intentions to guide the design of blast safeguards. The objectives should be related to preventing progressive collapse, protecting the occupants (saving lives and minimizing injuries), and limiting the damaging effects of blast (both inside and outside the building) to the extent possible given the design basis threats and physical limitations of structures and systems.

Design Basis Threats (DBT)

Establishing DBT is a mandatory first step in blast mitigation design. Following the process outlined in S850-12, the building owner and/or the authority having jurisdiction shall develop a building/project specific DBT based upon projected threat(s) identified in a TRA. It should be clearly understood that the DBT is to be used as a design requirement only and may not strictly represent an actual threat, in reality a DBT may be exceeded or may never be encountered over the life of the facility depending on whether, how, or if blast events occur.

Multiple DBT scenarios may be defined to account for multiple threat possibilities. Each threat scenario shall be defined in terms of charge size or mass, explosive type (or TNT equivalent) and location of explosive charge.

- Design Basis Threat (DBT)

- is the product of owner requirements. Each DBT shall be specified in terms of size, nature, and location of the blast source or blast loads. The building owner shall direct the performance objectives for the design consistent with the risk assessment. The performance objective shall include a desired overall building, component, or envelop LOP and may include further performance objectives. The DBT(s) shall specify the blast load(s) or scenarios for which the building is to be designed.

Building Levels of Protection (LOP)

The CSA S850-12 standard proposes protection schemes, which range from Low protection to Very high protection. Very high protection measures are generally extremely expensive and complex to implement, operate and maintain. As with DBT, defining LOP is part of the mandatory requirements for blast mitigation design.

Based on the probability of occurrence, asset criticality and associated costs, a variable approach to the application of LOP may be adopted. Building owners may apply various LOP's across a building portfolio or selected areas within a singular building depending upon the assets being protected or the criticality of operations.

Building and structure Level of Protection (LOP)

- Very Low (VL)

- classified as "collapse prevention". Progressive collapse is mitigated, but safe re-entry into the building is unlikely. Surviving occupants should be able to evacuate. Contents of the building might not remain intact

- Low (L)

- classified as "life safety". Progressive collapse is possible, but repair might be costly. Evacuation and temporary return of surviving occupants are likely. Building contents intact but not functional

- Medium (M)

- classified as "immediate occupancy". Structural damage is possible, but repair is economically viable. Temporary evacuation of occupants might be necessary, but re-entry and return to operation are possible after clean-up and repairs. Building contents are likely to remain at least partially functional

- High (H)

- classified as "operational". There is only minimal local damage. Operations and occupancy are relatively unaffected, with contents typically remaining fully functional

Building component and envelope damage

CSA S850-12 also considers damage to building components such as primary, secondary and non-structural components rating damage from Superficial to Hazardous. Other elements of the building envelope including glazing and doors are rated as well. Glazing damage is rated from Low hazard to No break while door damage is rated from Category I to Failure. For more details on building component and envelope damage rating, refer to the CSA S850-12 Standard.

Blast studies/consultants

Once the requisite DBT and LOP have been established for any given building or portion thereof an analysis should be conducted by a person holding a professional certification as a qualified blast engineer. This professional can verify assumptions regarding the assumed blast performance of the structure under consideration. All walls, floors, windows and doors should be considered in the analysis.

In order to ensure consistent application of blast mitigation the physical security team of the GC department or agency should work with the blast consultant to review the project strategy to ensure blast mitigation methodologies form part of a holistic threat mitigation strategy across the building/facility (and across the department or agency, if appropriate).

Design options and studies for any given project should be carried out to determine the best and most cost-effective methods that could be used to harden and mitigate, to the highest levels possible, the effects of blast. The advancement of technologies and knowledge related to blast mitigation is constantly evolving and new mitigation methodologies may become available over the course of a project and should be considered. [The Defense Research and Development Canada (DRDC) program to test and evaluate the effects of blast on buildings of 'historic' construction is an example of ongoing research and development].

Blast mitigation plans and concepts should be designed with to any seismic mitigating systems that are planned. Further, analysis of all seismic interventions should be conducted in order to identify any potential synergies with or detractions from blast mitigation systems.

When selecting a blast consultant, the following elements should be considered in the contract documents:

- Blast design experience

- In-house or outsourced expertise

- Credibility

- References

- Security clearances

When reviewing consultants' reports and deliverables the technical authority should:

- ensure blast mitigation analysis and proposals are sound

- conduct technical review

- review proposals by 3rd party (peer)

- ensure products/systems recommended are tested against accepted standards

Mitigations - Setback (stand-off) distance

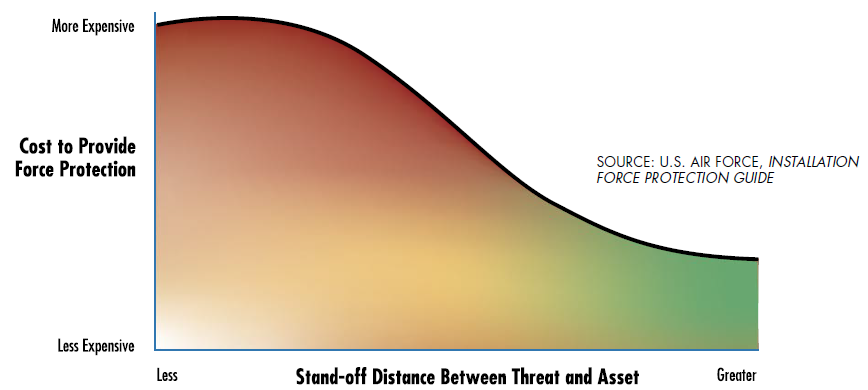

Energy from a blast decreases rapidly over distance. In general, the cost to provide asset protection will decrease as the distance between an asset and a threat increases, as shown in Figure 6-1. However, increasing standoff also requires more property and more perimeter to secure with barriers, resulting in the need to increase perimeter hardening mitigation measures to provide the required level of protection.

Figure 6-1 - Text version

Figure 6-1 is a graph depicting the cost relationship between force protection over stand-off distance. The vertical line of the graph depicts the cost to provide force protection. At the base of the axis, the cost is less expensive and the top of the line, the cost to provide force protection increases to more expensive. The horizontal line of the graph represents the stand-off distance between threat and asset. Along this horizontal line, the stand-off distance between threat and asset is rated from less to greater. As the blast wave decreases over distance from the asset, the threat increases from less to greater and is thereby more expensive).

Pedestrian setback zones

In instances when public access to the areas near a facility must be maintained but there is a risk of PBIED attack identified in the TRA; every effort should be made to establish suitable zones to detect and deter unauthorized access to the façade of the building.

The following application of zones should be considered:

Exclusion zone

- An area directly adjacent to the façade of a building should be established that is continually monitored by human and electronic means

- All unauthorized persons entering this area should be asked to leave the zone. No items should be left unattended

- The Exclusion Zone should extend out from the façade a minimum of 3m (10 ft.)

Watch zone

- An area beyond the exclusion zone should be established that is monitored by security personnel in the locale and augmented by electronic systems

- Items being brought into the area estimated to be 25 kg (50 lb.) or greater shall be closely scrutinized and /or manually inspected by security personnel. Examples include large packages, suitcases, bags, strollers, carts etc.

- The Watch Zone shall extend out from the façade minimum of 30 m (100 ft.) on average

Barriers and CPTED

The Watch Zones and Exclusion Zones should be delineated using a combination of common CPTED techniques including landscaping, walls, berms, sculptural or seating barriers.

Obvious, yet decorative natural or built elements should be used to clearly illustrate to the public that they are not to approach the façade. Natural elements such as plants, landscaping or topography should guide visitors away from the façade. Built elements such as decorative fences and signage shall deter and make obvious that entry is restricted.

Signage should be installed that advises the public that their actions are being monitored while in the Watch Zones. Paths and walkways should be laid out such that they create the greatest possible standoff available. Points were the pedestrian walkways and paths must pass into the exclusion zone should be restricted to those areas where access to entry points is a necessity. At no other point should pedestrian paths cross into the exclusion zone.

Vehicular setback

In order to maintain setback distances, it is extremely important that vehicle inspection facilities and barrier systems at a buildings perimeter remain fully functional, effective and operational. In the event that perimeter systems fail to maintain setback, design assumptions and building mitigations would no longer be valid.

Vehicular access to roadways adjacent to the facility should be restricted to only those vehicles that have been fully vetted and inspected at a vehicle inspection facility or other trusted facility. Notwithstanding the expected 'clean' nature of vehicles on such roadways, parking around the perimeter of the building needs to be minimized within the 'watch zone'.

Hostile vehicle mitigation

Vehicle access restrictions are a viable method to create setback. Protective measures capable of holding back an impacting vehicle are required.

- "Administrative" controls can be created by means of organizational or operational measures such as bans on stopping in a certain area, but these measures cannot prevent the close approach or parking of potentially hostile vehicles. However, parked cars are a recognizable threat and evacuation of the area or other appropriate security countermeasures can be undertaken.

- Furniture, planters and fixtures in public spaces can be used as structural protection devices for drivable surfaces. These devices form protection systems that prevent or inhibit driving (driving obstacles) close to a building/facility, but they are generally not able to restrain a vehicle deliberately driven at a high rate of speed.

- Systems built to withstand the impact of vehicles are used as vehicle restraint systems. Their design is geared to the threat involved, which in turn, is based on the expected design vehicle class (vehicle mass) and the impact speed of the vehicle. Typical vehicle restraint systems are bollards, barriers, and walls, which can come in the form of precast concrete walls or in-situ concrete walls.

Perimeter intrusion detection

In order to maintain setback, the [exclusion] and [watch] zones should be monitored electronically to detect pedestrians or vehicles approaching the building façade. Electronic intrusion detection devices should be deployed outside the building perimeter to provide sensing and notification of potential breaches of the standoff zone.

In cases where public access is allowed within a setback area, a human monitoring and response program should augment physical security elements. Departmental security teams should define operational requirements and zone coverage taking in to account operational and environmental conditions when establishing this program. These programs may consist of human resources monitoring setback areas to detect and interdict unauthorized access to a building's façade.

All available perimeter intrusion technologies should be considered, including infrared beam, video motion, "leaky" coaxial cable, microwave, fiber optic, electrostatic, taut wire, radar and any other viable technologies. Perimeter intrusion technologies being considered should be used in tandem with security video monitoring.

Perimeter intrusion infrastructure servicing the [exclusion] or [watch] zones are to have their associated electronic access control and monitoring controllers and infrastructure physically separated to provide zoned or partitioned access control and alarm point monitoring. Any exterior publicly accessible perimeter intrusion components shall be in conduits and physically secured junction boxes complete with tamper alarms. Internal conduits used for perimeter intrusion running through in public or operations zones shall be tamper-resistant with lockable/secured junction boxes.

Perimeter video monitoring

A security video monitoring system should provide integration, recording, display and management of video cameras meant to monitor the [exclusion] or [watch] zones. A combination of post and wall-mounted fixed, Pan-Tilt-Zoom (PTZ), Mega-Pixel (MP) and 360° cameras may be used to achieve the monitoring objectives.

Security video monitoring components are one of the most complex subsystems of any security system. Given the complexity and the importance of the facilities where the system will be deployed, it is strongly recommended that the design team include highly experienced and expert members who are conversant with security video monitoring applications, operation, limitations, technology, and all other considerations.

The objectives of the security video monitoring system used to monitor the setback area should:

- provide an ability for the identification and/or recognition of individuals approaching and/or entering defined zones

- provide assessment of alarm events and activities

- provide observation of zones or areas during events

- facilitate research, analysis and forensic investigations by using recorded video stored within the Video Management System

- serve as a platform for the potential future application of software automation and analytics

Cameras should be discretely, but not covertly integrated into the design of the environment depending on the capture strategies and recording requirements of each camera location.

Considerations

The goal of protective design against the effects of blast is the protection of the building occupants and the reduction of casualties. Economically feasible design for antiterrorism/force protection (AT/FP) requires an integrated approach to facility siting, operation programming of interior spaces, employment of active and passive security measures employing both technological security provisions and human security provisions.

The building's exterior is its first real defense against the effects of a bomb. How the façade responds to this loading will significantly affect the behavior of the structure. The comprehensive protection of occupants within the structure is likely to cause window sizes to decrease in height and width, yet increase in thickness, and attachments to become more substantial.

Considering the extent of surface area enclosing a building, even modest levels of protection will be expensive. As a result, the design philosophy might best be served by concentrating on the improvement of the post-damaged behavior of the façade. In order to protect the occupants to the highest degree, the aim should be for the building and its cladding components to remain standing or attached long enough to evacuate every person and to protect occupants from injury or death resulting from flying debris.

Mitigation methods

The following are examples of blast mitigation methods that may be used to limit the ingress of blast pressures through walls and windows. These should preclude collapse or localized wall failure, and limit injury caused by flying debris during a blast event:

- Hardening of exterior and select interior walls and roof structures from the interior through the use of steel framework and/or the application of fiber reinforced polymers (FRP)

- Connection of wall components through pins or other forms of mechanical fastening

- Installation of laminated glass within new window frames and suitable anchors to match the blast design for adjacent walls and DBT

- Application of laminated interior glazing where heritage windows are to remain

- Optional installation of window or wall 'catchment' systems to augment blast mitigation and capture flying debris in selected areas [Tie backs, seismic ties]

New versus existing construction

The complete renovation of a building allows for the installation of hardening solutions that would otherwise be virtually impossible under normal operating conditions. Methods to provide wall hardening can be economically installed during major renovations to provide modest protection from blast at near range and excellent protection from far range. Interventions during renovation are orders of magnitude less expensive than while spaces are occupied.

It should be noted that blast hardening will be in place over the long term and will establish fixed blast performance until the next renovation is undertaken. Mitigation techniques deployed during renovations should be robust enough to offer protection as threats evolve, diminish and rise again. Blast performance will be fixed once mitigation is in place, therefore in the event that threats increase to a point beyond the limits of the mitigation, alternate strategies such as scaling back to essential services or relocation of services and personnel should be undertaken.

In new construction, the available options for blast mitigation are greater in that mitigating measures can be designed into the structure and envelope at the time of design development. Existing structures are far more limiting since the mitigation must coexist with at least some portion of the existing structure. Heritage buildings using dated construction techniques present added complexity, which will limit the amount of mitigation that can be deployed. Specialized skills and innovative thinking are required to develop cost effective blast solutions.

Temporary structures

The use of temporary and semi-permanent structures such as mobile kiosks, weather shelters, tents, pergolas and sunshades should be minimized in an effort to decrease the amount of flying debris in the event of a blast.

Where such structures are necessary, their performance in a blast event should be considered in the overall design approach – location, anchoring, and construction details can significantly alter the impacts these structures would have on the facility and occupants.

Exterior walls and structure

All exterior walls and associated structural components of a building at risk shall be designed to withstand the effects due to blast as per the DBT and LOP. Complex architectural shapes and overhangs that cause multiple reflections of the blast wave should be discouraged.

Structural elements shall be designed such that stability during a blast event is achieved by transferring loads from any locally damaged region to adjacent regions capable of resisting those loads without progressive collapse by providing sufficient continuity, redundancy, or energy dissipating capacity (ductility, damping, hardness, etc.), or a combination thereof, in the members and connections of the structure.

Weight supporting exterior walls of unreinforced masonry shall be hardened to resist blast loading where required and secured through the application of membranes, pins, additional structural framework or some other suitable means.

Beam to column connections should be enhanced to limit connection damage and column designs should be improved to withstand loading specific to blast - in addition to normal structural loading (see section 7.5).

Buildings with masonry infill walls, brick veneer, or steel stud walls are particularly susceptible to blast loading. Although robust in appearance, masonry walls are typically very brittle, and tend to fail under low blast loads. This must be considered as part of a blast analysis. Masonry infill walls and brick veneers may separate into additional flying debris during a blast event, which can then cause further injury to occupants and damage to assets. Steel stud walls lack stiffness to resist high lateral pressures. Connections of masonry, veneer or stud walls to the structure must be examined in detail and retrofits would be required in most instances.

Wall retrofit systems in use today include:

- Elastomeric sprays

- Fiber-reinforced polymers (FRP) sheets

- Geotextiles

- Steel plates

- Concrete skins

Columns

Frame buildings designed to resist gravity, wind and earthquake loads in the normal way have frequently been found to be deficient when subjected to blast loading due to the failure of beam-to-column connections and the inability of the structure to tolerate load reversal. Beam-to-column connections can be subjected to very high forces as the result of an explosion (Figure 4-3). These forces will have a horizontal component arising from the walls of the building and a vertical component from the differential loading on the upper and lower surfaces of floors. Providing additional robustness to these connections can be a significant enhancement.

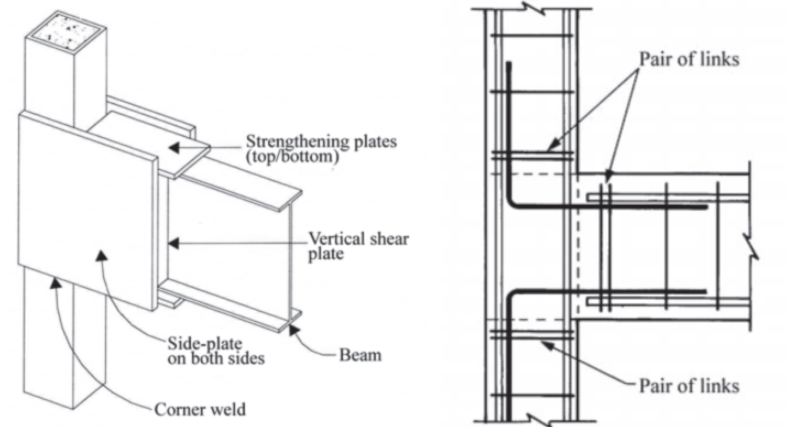

Typical building column and beam connections for static loading have been found to be inadequate for blast loading. Especially for the steelwork beam-to-column connections, it is essential for the connections to be designed so that frames can still operate after an explosion. Figure 7-1 shows examples of enhanced connection details. The main features to note in the reinforced concrete connection are the use of extra links relative to the location of the starter bars in the connection. These enhancements are intended to reduce the risk of collapse or damage to the connection to the beam.

Figure 7-1 - Text version

Figure 7-1 depicts beam to column construction as defined in paragraph 7.5 Columns. Figure 1 illustrates beam to column construction. The column runs vertically while the beam runs horizontally. This construction consists of bottom and top strengthening plates, vertical shear plates, side plates on both sides of the column and a corner weld. Figure 2 demonstrates enhanced connection details on both the vertical column and the horizontal beam. Pairs of links are installed inside the column and beam to reinforce the concrete connection at the starter bars location of the connection.

Columns are also susceptible to failure if subjected to explosive events nearby. Columns are predominantly loaded with axial forces under normal loading conditions however under blast loading; they may be subjected to bending. A relatively small charge placed on or near a column could cause failure of the column and possible collapse of the supported structure. Retrofit methods are available including carbon fiber-reinforced polymers (CFRP) and steel jacketing systems can be used to help mitigate damage to columns subjected to blast.

Windows

Glazing, often the most vulnerable material near a bomb blast, must withstand two blast effects to offer protection. The first effect is the shock or blast wave, which travels from the explosive charge in all directions as it detonates. The second is caused by fragmentation from the munition or material in the vicinity propelled by the explosive.

Ordinary glazing can contribute to the destructive potential of a blast. This is because the destructive result of a bomb blast is magnified when it propels fragments such as glass. Unprotected window failures account for most injuries during a blast event, for example, 66% of the injuries sustained during the Oklahoma City bombing was attributed to flying glass. Glazing intended to offer increased safety in a blast situation must be designed to be retained in the frame of the window based on the expected DBT and LOP.

The design of the window frame – and methods used to attach to the wall - is significant in determining the effectiveness of the protection offered by the window/frame system. Further, the window system will transfer all blast loads to the wall therefore the wall and structure construction must also be considered, and be robust enough to assume all expected loads.

Testing of glass resistance to bomb blasts is best performed using the actual frame/wall to be used with the glazing. It should be noted that 'open frame testing' is not the most accurate as it does not enclose the frame in any structure and does simulate the environment accurately.

The ASTM test protocol "Standard Test Method for Glazing and Glazing Systems Subject to Air blast Loadings" ASTM F 1642 (21) is an often-used test procedure in the North American Market. Other test methods may be used when deemed equivalent by a blast engineer.

- Annealed glass

- sometimes called standard or float glass, is a softer low-cost glass that has been thermally treated and then slowly cooled to relieve any internal stresses. Annealed glass tends to break into longer, jagged shards, which can cause significant injury. It is generally used when strength, safety or security are not concerns.

- Wired glass

- is annealed glass, which contains a wire mesh embedded inside the glass. It is intended to be used to satisfy building code requirements for fire protection. The impact resistance and breakage pattern of wired glass is similar to annealed glass. Wired glass is intended to remain in place during a fire even after it has been exposed to the heat of the fire and then subjected to a stream of water from a fire hose (thermal shock). Wired glass is not an effective alternative for blast mitigation.

- Tempered glass

- also known as toughened, tempered glass is produced by heating a piece of annealed glass until it reaches its softening point, and then chilling it rapidly. This changes the stresses in the glass, leaving the surface in compression while the center remains in tension. The result is that tempered glass is much more difficult to break, having approximately three to five times the strength of annealed glass. When broken, the entire sheet of tempered glass disintegrates into small cube-like pieces which are less harmful than the dagger-like shards that annealed glass produces.

- Chemically strengthened glass

- is a type of glass that has increased strength as a result of a post-production chemical process. When broken, it still shatters in long pointed splinters similar to float glass. For this reason, it is not considered for blast mitigation. However, chemically strengthened glass is typically six to eight times the strength of float glass.

- Heat-strengthened glass

- is approximately twice as strong as annealed glass, heat-strengthened glass is created by a process similar to tempered glass, except the cooling process is not as rapid. Although not suitable for blast mitigation, heat-strengthened glass provides increased impact resistance where the added strength is required because of high thermal and wind loads. Heat-strengthened glass is not at risk of spontaneous breakage (a risk inherent in tempered glass). If heat strengthened glass should break, the pieces will be larger and less likely to fall out of a window frame.

- Laminated glass

- is made by sandwiching a thin layer (often as thin as 0.015 of an inch) of polyvinyl butyral (PVB) resin or similar bonding agent between two or more layers of glass. The glass and plastic are bonded together using heat and pressure. The resistance of laminated glass is essentially similar to that of non-laminated glass. However, when the laminated glass is broken, the plastic sheet holds the broken pieces of glass in place. The glass used in manufacturing laminated glass may be either annealed or tempered and may also be tinted or treated with other coatings. Laminated glass may be used in combination with other glass types in insulating units. Laminated glass is often used to mitigate the effects of blast.

- Acrylics and polycarbonates

-

is plastic glazing material manufactured using either acrylics or polycarbonate. Both materials have several advantages and disadvantages. The clarity of vision is superior with acrylic than polycarbonate interlayer. Acrylic's impact strength is approximately 17 times greater than glass, while polycarbonate is about 300 times stronger than glass. Both acrylic and polycarbonate are about 50% lighter than glass of equal thickness. Polycarbonates are well suited for blast mitigation.

Although both acrylics and polycarbonate materials have excellent impact strength qualities, they share several disadvantages. Both materials will scratch easily and will deform under heat. Although mar-resistant coatings are available, the glazing will still mar easily if scratched with a penknife or stone. Acrylic burns vigorously, while polycarbonate burns to a lesser degree and local code restrictions may affect usage.

- Glass Clad Polycarbonate

- is a strong and optically transparent material. It is particularly resistant to penetration by projectiles although, like other material, it is not impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter and is often constructed using layers of laminated glass. The more layers there are, the more protection the glass offers. When a weight reduction is needed 3mm of polycarbonate (a thermoplastic) is laminated onto the safe side to stop spall. The aim is to make a material with the appearance and clarity of standard glass but with effective protection from small armsFootnote 5. Glass Clad Polycarbonates are well suited for blast mitigation.

- Anti-shatter Film (ASF)

- the application of ASF is one method of reducing the damaging effects of non-laminated glass being projected during a blast event. ASF consists of polymer or polyester films with high tensile strength and deformation capacity. When adhered to glass they bind glass shards and help mitigate against glass shard injury. ASF can be used to increase window performance with respect to total solar transmittance, reflectance or absorption. They can also provide protection against UV light and EMSEC threats.

- ASF - Daylight application

- film is applied directly to the visible portion of the window glazing and does not require removal of the window from the frame. The film is typically cut to within 1.6mm from the window edge. The primary purpose is to hold glass fragments together during breakage. The result is that instead of a series of small shards, the window fails as a large cracked and broken sheet. Although this decreases the risk of being hit by a mass of individual fragments, the likelihood of significant blunt trauma increases particularly when film is attached to tempered glass, therefore great care must be taken when selecting daylight film as a mitigation for blast.

- ASF – Edge-to-edge installation

- film is applied to the glazing after the window 'stop' has been removed and applied from one edge of the glass to the other. Once reinstalled this method relies on the window stop to capture the window and film within the frame.

- ASF – Wet glazing

- is similar method to daylight application with structural silicone bead applied around the periphery of the daylight film area to effectively join the film to the widow stop/frame. This helps to reduce the likelihood of complete window separation and resultant blunt trauma. Note that the window stop/frame will now bear the blast load and must be suitably robust to accept these loads. With stops removed, wet glazing may also be applied in an 'edge-to-edge' fashion as well for added blast resistance.

- ASF – Mechanical fastening

-

is the preferred method for installing ASF to a window yielding improved blast resistance and decreased risk of blunt trauma. Mechanical fastening is the least cost effective and the most time consuming of ASF application methods. The film is cut so a small amount of film extends over the frame and is secured using battens or strips along its edge to secure it to the frame.

ASF mechanical fastening can be applied along the top edge to allow the glass to rotate or swing inward away from the frame allowing some ingress of blast pressure while limiting the likelihood of complete window separation. Two and four-sided mechanical fastening provides the most protection, however regardless of the method, great care should be taken to ensure that frame and wall loads transferred from the glazing can be withstood.

Doors

Although not as vulnerable as windows, unmitigated commercial doors are likely to fail under modest blast loading causing ingress of blast pressure, debris and possible injuries. Doors that are designed to withstand blast loads can be extremely expensive, complex and heavy, requiring specialized hinges and door operators. Most blast doors are custom built for each application and require a level of maintenance that is much higher than commercial doors.

Most blast doors typically exceed the maximum pull force required to meet National Building Code requirements thus these doors cannot normally be opened manually. Power operators are usually required resulting in increased dwell time while opening and closing. These large doors may also impact security operations and create user difficulties.

Given the added operational complexity, cost of installation and ongoing support required, great care must be taken when adding blast doors to blast requirements. Consideration must be given to the Level of Protection (LOP) required, in other words, blast doors should be specified and installed only in instances that are fully justified by a TRA and subsequent blast DBT/LOP.

Blast doors must be designed to be operable after an explosion event and must not hinder evacuation. As with blast resistant windows, blast doors, frames, hardware and wall attachments must be designed as a complete system. Coordination between door suppliers, designers, security practitioners and the project design team is essential to ensure a smooth installation.

Blast door styles

- Hollow metal blast doors

- constructed by spot welding a blast resistant steel plate(s) onto hollow steel sections (HSS). Steel sheet thickness < 4.5 mm to accommodate welds. HSS can be made from HSS 51x51 typically. This type of door is not very effective against fragment impact.

- Structural steel plate blast doors

- these doors are least expensive because of lower fabrication cost. Structural steel plate door with aspect ratio >2 is effective in reducing deflections. Steel plates with a thickness of > 200mm are available COTS. Door size is limited by the weight of steel.

- Built-up structural steel blast doors

- constructed by welding a blast resistant steel plate onto steel shapes (H channel, Z stiffeners or S Shapes). S-shapes are preferred because of narrow flanges. Typically used where spans do not allow use of structural steel plates. Amount of welding required can dramatically increase fabrication cost. Welding can lead to warping of members. In addition, because welds are concealed, inspection of welds could be required.

- Reinforced concrete blast doors

- consists of a doubly reinforced concrete panel cast into a structural steel channel frame. Steel reinforcement bars are often welded to the structural steel frame. A steel spall plate is provided at the interior side to prevent injury from concrete scabbing. These blast doors are cheaper to construct and install but can be very heavy and difficult to operate and open/move.

Hardware considerations

- Door frame

- Anchored into structure usually a sub-frame is cast into concrete.

- Hinges

- Consider rolling bearing or rolling nonbearing type hinges. Rolling bearing type is easier to operate but more susceptible to damage.

- Latching

- Multiple latch points required. Operated by single or multiple lever type handles or a wheel handle.

Entry points and reception areas

Entry points and reception areas present a unique challenge in that these spaces are where the public interfaces with the protected building. Unless pre-screening of visitors is conducted, reception areas are particularly vulnerable to attack using explosives. Reception areas may offer a perceived point of entry by an attacker and in the event that the attack is interrupted, the attacker is presented with potential alternate targets in the form of visitors being processed in the reception area.

When an explosion occurs within a reception area, the pressures associated with the initial shock front will be extreme and will be amplified by their reflections within the space. This type of explosion is called a confined explosion. In addition, and depending on the degree of confinement, the effects of the high temperatures and accumulation of gaseous products produced by the chemical reaction involved in the explosion will cause additional pressures and increase the load duration within the structure.

Given the vulnerability posed by reception areas a 'hard line' should be established between reception areas and the controlled zones effectively limiting the effects of overpressure and flying debris on occupants of the controlled zones. Hard line walls, floors and ceiling enclosing the reception zones (other than venting systems) shall be designed and built with material selected to withstand the design loads caused by defined threats found within the DBT. Security staff in the case of visitors without credentials shall control Access through portals across the 'hard line'.

Reception areas and processes should be located along exterior walls or ceilings to allow for venting overpressure due to blast. Where frangible systems are used to allow for blast venting, consideration shall be given to personnel and visitors in the areas near the vent to limit injury and damage in the event of blast.

In order to limit flying debris and fragmentation, false or suspended ceilings and other 'loose' architectural elements should be minimized in the reception areas, to the greatest extent possible. Further, all mechanical and electrical equipment, including but not limited to, ductwork and hanging light fixtures within the reception areas should be securely fastened and restrained in a robust manner to limit flying debris.

Where damage and system failure due to a blast event are beyond anticipated loads, every attempt must be made to confine damage by developing design strategies to allow for failure with minimal impact. Areas within a building that are above or below the reception areas shall be protected from overpressure, flying debris and structural failure caused by an explosive event within the reception areas.

Exposed columns running through the reception areas, which if targeted with explosive, would cause structural collapse, should be avoided or otherwise protected to withstand design loads caused by expected blast threats.

Egress routes

Where damage due to a blast event is beyond design loads, every attempt should be made to confine damage by developing design strategies to allow for failure with minimal impact. The design should provide, at a minimum, evacuation options when routes are unavailable following a blast. Egress routes should be designed to limit debris and door blockages to ensure relatively clear passage following a blast event. Depending on architectural layout, protected and alternate egress routes may also need to be provided to ensure egress from affected areas.

Supporting content

References

- CANMET, Braimah and Contestabile, "Blast Vulnerability Assessment: Challenges and Myths", CERL Report 2007-16

- CSA, S850-12, Design and assessment of buildings subjected to blast loads, April 2012

- CANMET, Braimah et al, "A Summary of Blast Mitigation Strategies for the Protection of Buildings", 2005-10

- USAF, "Force Protection Battle Lab Vehicle Bomb Mitigation Guide", 2002

- SPIEZ LABS, Schuler, Burkel et al, "Mitigation of Terrorist Attacks with Vehicle Borne Improvised Explosive Devices Manual", Report no. LS2009-05, 2009

- Istanbul Technical University, Koccaz, Sutcu, and Torunbalci, "Architectural and Structural Design For Blast Resistant Buildings", 2008

- ABS Consulting, Barker – "The Case for Impulse - Analysis of Conventional Structures Subjected to Blast Loads", 2010

- Mays G.C., Smith P.D. (1995). "Blast Effects on Buildings", Thomas Telford Publications, Heron Quay, London.

- Punch S. (1999), "Blast Design of Steel Structures to Prevent Progressive Collapse", Structural Engineers Association Convention Proceedings, Santa Barbara, California, U.S.A.

- Hill J.A., Courtney M.A. (1995). "The structural Engineer's Response to Explosion Damage. The Institution of Structural Engineer's Report", SETO Ltd, London.

- Designers Notebook Blast Considerations Part 1

- FEMA 426, Explosive Blast, Chapter 4

- CANMET, Contestabile and von Rosen, "A Guide to Using Protective Film for Security Upgrades of Glass Windows" (DRAFT), 2003-15

- Karagozian & Case, "To Film or not to Film, Effects of Anti-shatter Film on Blunt Trauma Lethality from Tempered glass", 2002

Promulgation

Reviewed and recommended for approval

I have reviewed and hereby recommend GCPSG-002 (2021) - Blast Mitigation Considerations Guide for approval.

Shawn Nattress,

Manager

RCMP Lead Security Agency

June 30, 2021

Approved

I hereby approve GCPSG-002 (2021) - Blast Mitigation Considerations Guide.

André St-Pierre,

Director, Physical Security

RCMP

June 30, 2021

Footnotes

- Date modified: